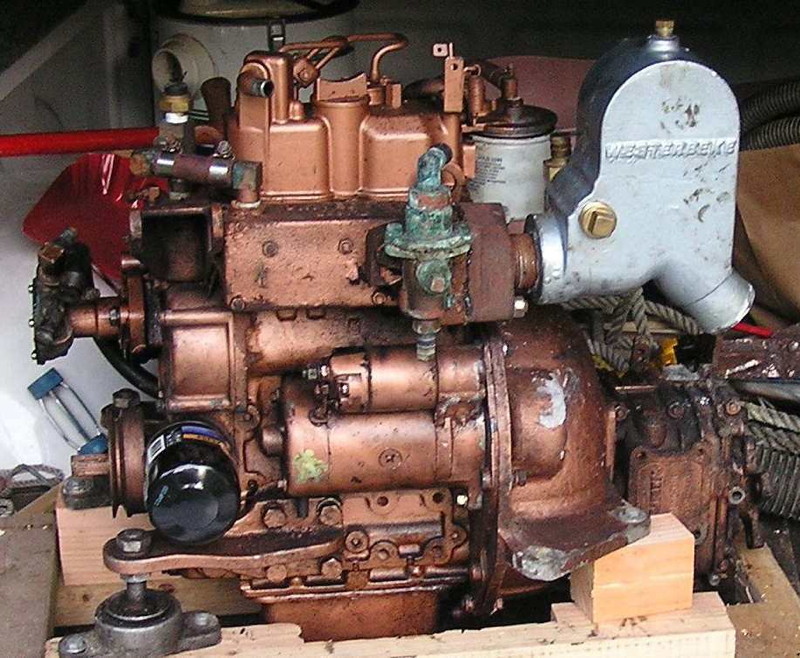

This is the old riser after removing and cleaning it.

In September 2005, "Corleto," my Catalina 27, was due for a haul out. She had been at the dock unused for two summers and while the hull was still free of any hard growth, I had plenty to break off of the propeller and shaft before I could expect more than just a few knots speed. That was mistake number one, not using a boat for that length of time. It's a 30 mile trip to the nearest haul out and use of the engine has always proven necessary going north. After some effort with a long handled brush at the dock to break off the growth, I took her out for a short motor out of the marina and back to make sure she could make 5 knots, which she did. My second mistake was that I had forgotten that the Hood Canal Bridge would be closed the following week and that we had a trip planned the following three weeks, so I called and postponed my haul out for a month. The third mistake was that I had never guessed that barnacles and mussels could grow back in one month if the surface is not cleaned well. One month later, shortly after leaving the dock, I realized my GPS speed was only three knots and that I would never be able to reach the haul out point on one tide interval at that speed. I did not have enough time to return to the dock to clean the propeller and still meet my haul out time so I speculated that since the growth was so new, I might be able to wear it off with more RPMs. That was mistake number four and resulted in a smoky exhaust, extra vibration, and finally a loud thump! from the engine. Smoke was now coming from inside the cabin and I shut down and looked below. All looked in order from below and I restarted but the smoke persisted. I opened the bilge cover to discover that a full flow of cooling water was flowing through the bilge. I shut down again and after opening the side panel I could see that the exhaust riser tee which feeds the bronze water injection fitting had fallen apart and I had exhaust and water spraying all over in the engine room.

This is the old riser after removing and cleaning it.

There was barely enough wind to sail but the full ebb tide had kicked in by this time. I decided to return to Kingston since I was only a mile or so away but with adverse current. Despite sailing across the Sound to Edmonds where there was less current, I was barely making headway towards Kingston. What ever chance I had to make it on my return tack was cut off by an outgoing container ship. By the time I made two tacks to let the ship pass, my wind was less and I had even more current. Faced with the prospects of spending the next ten hours getting Corleto back to Kingston under sail alone, I decided to let the engine idle and motor sail. That got me back to my slip in a more timely fashion, but made quite a mess inside the engine room.

In removing the mess, I managed to aggravated a 40 year old neck injury plus my tendonitis and was unable to complete the work until September 2006, after many months of physical therapy.

The old exhaust riser was wrapped 1 1/4" NPT pipe fittings with a bronze injection fitting. Westerbeke has taken over the Universal parts replacements and the new riser is a cast aluminum water jacketed riser which I obtained plus a new gasket for the manifold as my old riser adaptor fitting was still serviceable and the new riser is 1 1/4" NPT. I was troubled by the fact that the new riser sat 7 inches lower than the old riser, and is lower than the loop between the muffler and transom.

The new riser is shown here, attached to the engine.

My engine has a heat exchanger installed with the raw water flow provided by a FlowJet Quad Series pump with a 3.3 GPM output. This is a heavy flow and I was concerned that it might back up into the engine. I did install an anti

siphon valve in the feed line and when first running the engine, I only opened the cooling water cock after the engine was running and made sure I closed it before shutting the engine down. I cleaned the prop once again and motored the 60 miles round trip for the haul out with no problem. The engine and cooling seemed back in order at that time. In hindsight, that became mistake number five, because there were no safeguards against flooding the engine should the pump run and the engine not start.

In August 2007 the engine would not start. The starter would click but not engage. My first concern was I might have flooded the engine so in subsequent tries in getting the starter to work I tried to remember to not open the cooling water valve. I checked several times over the next year to make sure the engine turned freely, insuring me that I had not flooded the engine. Mistake number six was in not realizing that I had probably already flooded the engine at that point and may have even made it worse by rotating the engine.